See the Growth of 4D Printing Market

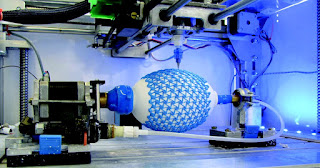

The process by which a 3D printed object turns into

another structure under the influence of external energy input such as

temperature, light, or other environmental stimuli is known as 4D printing. This

technique is part of the MIT Self-assembly Lab's initiative. The goal of this

project is to bring together technology and design to create self-assembly and

programmable material technologies that will reimagine building, manufacturing,

product assembly, and performance.

|

| 4D Printing Market |

The global 4D printing market was valued at US$ 82.6 Mn in 2020 and is expected to reach US$ 625.6 Mn by 2028 at a CAGR of 29.4% between 2021 and 2028. Commercial 3D printers, such as Polyjet 3D printers, are used in 4D printing technologies. A "smart substance," such as a hydrogel or a shape memory polymer, is used as the input. Smart materials are distinguished from typical 3D printing materials by their thermomechanical qualities and other material features, which allow them to change shape. Objects made with 3D Printing technology, on the other hand, have a stiffness to them. This means that 3D printed things will retain their 3D shape after printing.

4D printing technology is the addition of the fourth

dimension (4D) to the third dimension (3D). The generated 3D item can change

its shape by itself under the effect of external stimuli such as heat, light,

electricity, magnetic field, and others thanks to 4D. 4D printing refers to the

ability of items to change their structure over time by utilising the behaviour

of various materials, and it does not require human interaction. Furthermore,

the growing demand for flexible products in a variety of applications, such as

adaptable wind turbines, self-folding packaging, and others, has prompted the

development of 4D printing.

During the forecast period (2021–2028), the global 4D

printing market is expected to grow significantly. During the forecast

period, the global 4D printing market is expected to grow due to rising demand

for innovation in 3D printing applications and significant research and

development. The 4D technology is a more advanced variant of 3D technology that

provides better quality, efficiency, and performance than traditional

production procedures. 4D technology creates materials that can change their

behaviour and qualities in response to changes in temperature, pressure, and

other factors.

Pipes in a plumbing system that dynamically alter diameter

in response to flow rate and water demand are one possible application of 4D

Printing in the real world. Pipes that, because of their ability to adapt in

reaction to changes in the environment, may be able to mend themselves

automatically if they crack or break.

Due to the high level of competition, there is an increasing

desire to reduce production and processing costs, which is supporting future

market growth. Several businesses have begun to use advanced 4D printing

technologies to create high-quality products for their customers. These 4D

printing products have lower manufacture, transportation, and handling costs,

resulting in resource and effort savings and environmental sustainability.

For more Related

reports, visit- https://bit.ly/3MWMQRa

Comments

Post a Comment