4D Printing Market Overview, Restraints and Drive growth in R&D Investment, 2021-2028

|

| 4D Printing |

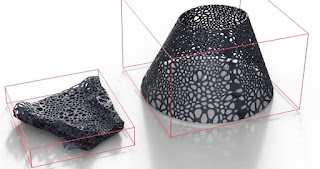

4D Printing Technology is the addition of the

fourth dimension (4D) to the third dimension (3D). The produced 3D item may

alter its shape by itself under the effect of external stimuli such as heat,

light, electricity, magnetic field, and others thanks to 4D. 4D printing refers

to the capacity of items to change their structure over time by utilising the

behaviour of various materials, and it does not require human interaction.

Furthermore, the growing need for flexible products in a variety of

applications, including adaptable wind turbines, self-folding packaging, and

others, has prompted the development of 4D printing.

During the projected period (2021–2028), the worldwide 4D printing market is predicted to increase significantly. During the projected period, the worldwide 4D printing market is predicted to rise due to growing demand for innovation in 3D printing applications and significant research and development. 4D technology is a more advanced variant of 3D technology that provides better quality, efficiency, and performance than traditional production procedures. 4D technology creates materials that can alter their behaviour and qualities in response to changes in temperature, pressure, and other factors.

According to Coherent

Market Insights, The global 4D

Printing Market was valued at US$ 82.6 Mn in 2020 and is expected to

reach US$ 625.6 Mn by 2028 at a CAGR of 29.4% between 2021 and 2028.

Due to the high level of competition, there is an increasing demand to

reduce production and processing costs, which will fuel future market growth.

Several businesses have begun to employ sophisticated 4D printing technology to

create high-quality items for their customers. These 4D printing items offer

lower manufacture, shipping, and handling costs, resulting in resource and

effort savings and environmental sustainability.

For the purposes of this market analysis, 4D printing is

defined as a technique in which the fourth dimension involves a change in shape

or function following 3D printing of Programmable Material (PM). In other

words, 4D printing allows items to be 3D printed and then self-transform in

shape and material property when subjected to a pre-determined stimuli such as

water, heat, pressure, electricity, ultraviolet light, or another source of

energy. Programmable carbon fibre, programmable wood grain, and programmable textiles

are the three material categories that make up the market. With a market share

of 62 percent in 2019, the programmable carbon fibre category is predicted to

be the greatest contributor to the entire market.

In the production process, 4D printing is projected to play

a significant role. The printing method allows for 1D or 2D printing of

programmable material, which then self-transforms into a 3D item according to

the encoded programme. The increased need to lower manufacturing and processing

costs while also ensuring a sustainable environment would fuel this expansion.

In the projected term, advances in Biofabrication technology

will boost the 4D printing market. When external energy sources, such as

pressure, heat, or energy, come into touch with this 3D printed smart material,

it changes according to the program's instructions. 4D

printing technology allows printed items to self-transform over

time in this way. The development of medical and defence technology is being

aided by technical developments in 4D printing. Doctors, for example, employ 4D

printing to implant self-transforming components into the patient's body to

reduce the number of operations required during surgery.

Comments

Post a Comment