Die Casting Market Analysis and Forecast up to 2028 with CAGR 7.2%

|

| Die Casting Market |

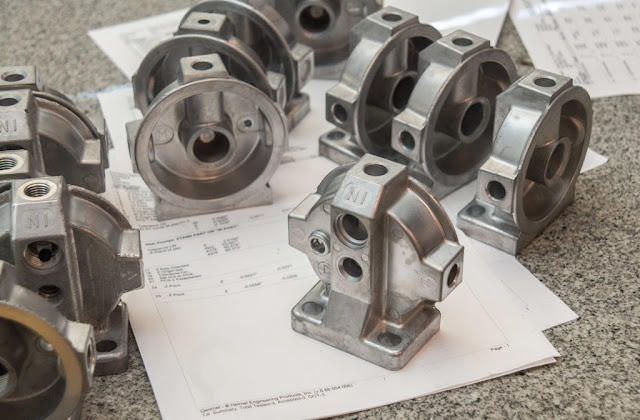

Die casting is a process of

producing geometrically complex metal components by using reusable moulds known

as dies. The metal, which is often a nonferrous alloy such as aluminium or

zinc, is melted in a furnace before being fed into dies in a die casting

machine. The process involves forcing molten alloy or metal into a mould cavity

under high pressure. Die castings are made from metals such as lead, zinc,

magnesium, aluminium, copper, and tin-based alloys.

The die casting business is

expanding as demand for fuel-efficient, high-performance, and low-emission

vehicles rises. Demand for die casting machines is being pushed further by an

expansion in the machinery manufacturing sector and an increase in construction

industry spending. The market's expansion is anticipated to be hampered by raw

material price volatility. Furthermore, there have been a number of

advancements in classic high-pressure die casting procedures in recent years.

Such factors are anticipated to present market participants with appealing

growth opportunities over the forecast period.

The global Die

Casting Market was valued at US$ 62.3 Bn in 2020 and is expected to

reach US$ 106.5 Bn by 2028 at a CAGR of 7.2% between 2021 and 2028.

To match new market trends, high

pressure die casting (HPDC) technology is continuously changing. As a result,

new die lubrication technologies are being introduced into the die casting

industry. These innovative technologies boost die casting plant productivity by

enabling casters to make high-quality and complicated castings at high die

temperatures while decreasing machine downtime.

In the vehicle die casting

business, China has the biggest market share. Due to covid-19, the global

economy and environmental rules had a big influence on Chinese vehicle exports

in early 2020. Recent global regulatory changes have had little to no impact on

the rate of sales growth in 2019.

The COVID-19 pandemic had a

significant influence on manufacturing operations, and the market experienced a

slowdown as a result of supply chain interruptions and trade restrictions

throughout the world. However, the global restart of economic activity is

expected to generate consistent growth over the predicted period. The supply

chain difficulties in the die casting industry, the developing automotive

market, the increasing penetration of die casting components in industrial

machinery, the growing constructional sector, and the use of aluminium castings

in electrical and electronics are driving the market examined. CAFÉ

requirements and EPA initiatives to decrease automotive emissions and boost

fuel economy are pushing automakers to use lightweight non-ferrous metals to

reduce vehicle weight. Subsequently, employing die-cast parts as a weight

reduction strategy is acting as a major driver for the former market in the

automotive segment.

As a result, using die-cast parts

as a weight-saving approach is a primary driver for the former market in the

automobile industry. However, a shortage of raw materials, volatility in raw

material costs, and environmental laws on emissions for the metallurgical

sectors are all important roadblocks to industry expansion.

Due to increased demand for

vehicles in countries like as China and India, as well as increased usage of

aluminium die casting for different applications, the Asia-Pacific region is

expected to have the biggest market share in the die casting Market. The

aluminium die casting market in North America is also predicted to rise

significantly due to increased output from the construction and automotive

industries.

Top Companies involved are- Alcast Technologies, Arconic,

Consolidated Metco, Inc., Dynacast International Inc., Gibbs Die Casting, Ryobi

Die Casting Inc., Bodine Aluminum, Martinrea Honsel Germany GmbH, Leggett &

Platt, Endurance Technologies Ltd., Empire Die Casting Company, Alcoa Inc.,

Hitachi Metals Ltd, Nemak S.A.B. de C.V., GF Casting Solution AG, Shiloh

Industries Inc., Rheinmetall Automotive AG, Sigma Electric Manufacturing Corp.,

Pace Industries, and Guangdong Yizumi

Comments

Post a Comment