Machine Condition Monitoring Market is Estimated to Witness High Growth Owing to Opportunity for Preventive Maintenance

|

| Machine Condition Monitoring Market |

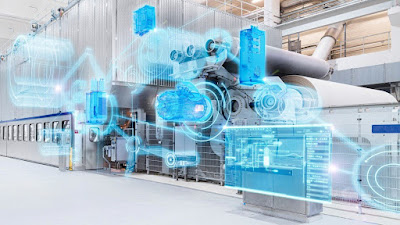

Machine condition monitoring involves monitoring equipment like motors, pumps, gearboxes and other mechanical rotating equipment for faults and failures. It helps detect early deterioration of components leading to failure, thus enabling preventive maintenance. Regular inspections with machine condition monitoring tools help identify issues before they escalate, reducing downtime and repair costs.

The global

machine condition monitoring market is estimated to be valued at US$3965.6

million in 2023 and is expected to exhibit a CAGR of 5.8% over the forecast

period 2023 to 2030, as highlighted in a new report published by Coherent

Market Insights.

Market Opportunity:

The key opportunity for preventive maintenance through machine condition

monitoring provides a significant boost to the market growth. Machine condition

monitoring tools help detect faults in equipment at an early stage, thereby

facilitating planned and preventive maintenance measures. This helps avoid

unexpected breakdowns and reduces downtime significantly. Preventive

maintenance through machine condition monitoring improves equipment

reliability, extends their useful life and lowers overall repair and

maintenance costs in the long run. It decreases unscheduled production

stoppages and losses due to failure of critical assets like motors, pumps etc.

The cost savings from improved asset availability and reliability drive greater

demand for machine condition monitoring systems for preventive maintenance

applications across industries.

Porter’s Analysis

Threat of new entrants: Low as it requires substantial initial investments and

expertise to establish in this market. Significant economies of scale and

experience curve advantages hold by existing players.

Bargaining power of buyers: Moderate as buyers have some purchasing power being

large organizations, however switching costs being higher due to customized

product integration.

Bargaining power of suppliers: Low as suppliers are fragmented and raw

materials for machine condition monitoring systems are commodity items with low

differentiations.

Threat of new substitutes: Low as machine condition monitoring systems provide

unique benefits over conventional techniques like vibration analysis.

Competitive rivalry: High among existing players due to their significant

investments and product differentiations.

SWOT Analysis

Strengths: Non-invasive technology, remote connectivity features, predictive

maintenance capabilities.

Weaknesses: High initial investments, expertise required for installation and

data analysis.

Opportunities: Growth in Industry 4.0 trend, increasing adoption across process

and discrete industries.

Threats: Cybersecurity risks, challenges integrating with legacy systems.

Key Takeaways

The global machine condition monitoring market is witnessing increasing

traction from process and discrete industries for predictive maintenance of

critical assets and reduction in unexpected downtimes. Global

Machine Condition Monitoring Market Size is estimated to be valued at

US$3965.6 million in 2023 and is expected to exhibit a CAGR of 5.8% over the

forecast period 2023 to 2030.

Regional analysis comprises North America accounts for the largest share

primarily due to early technology adoption and presence of leading players in

the US and Canada. Europe and Asia Pacific are other major regions with

sizeable shares owing to established manufacturing sectors. With rising

industrialization and manufacturing activities, Asia Pacific region is poised

to witness the fastest growth during the forecast period led by China, Japan,

India, South Korea and other Southeast Asian countries.

Key players operating in the machine condition monitoring market are Applied

Sciences Inc., Argon, FLIR Systems, Hexagon and National Instruments. Key

players are focused on new product launches, partnerships and mergers &

acquisitions to strengthen their market position and gain access to new

regions. They are also investing in research & development to develop

advanced systems with integrated connectivity, cloud capabilities and

analytical tools for predictive maintenance.

Get More Insights on this Topic- https://www.dailyprbulletin.com/machine-condition-monitoring-market-size-share-and-demand/

Comments

Post a Comment